Turkey steps closer to becoming engine design, manufacturing center

Turkey is well on its way to becoming design and manufacturing center for all kinds of engines, especially in aviation, President Recep Tayyip Erdoğan said as the country moved closer to mass producing local turboshaft helicopter engines.

Turkey is well on its way to becoming design and manufacturing center for all kinds of engines, especially in aviation, President Recep Tayyip Erdoğan said as the country moved closer to mass producing local turboshaft helicopter engines.

“With these projects, we’re entering a new era in the defense industry,” Recep Tayyip Erdoğan told the handover ceremony for Turkey’s first indigenous helicopter engine and opening of new design center via a live video link from the Vahdettin Mansion in Istanbul on Saturday.

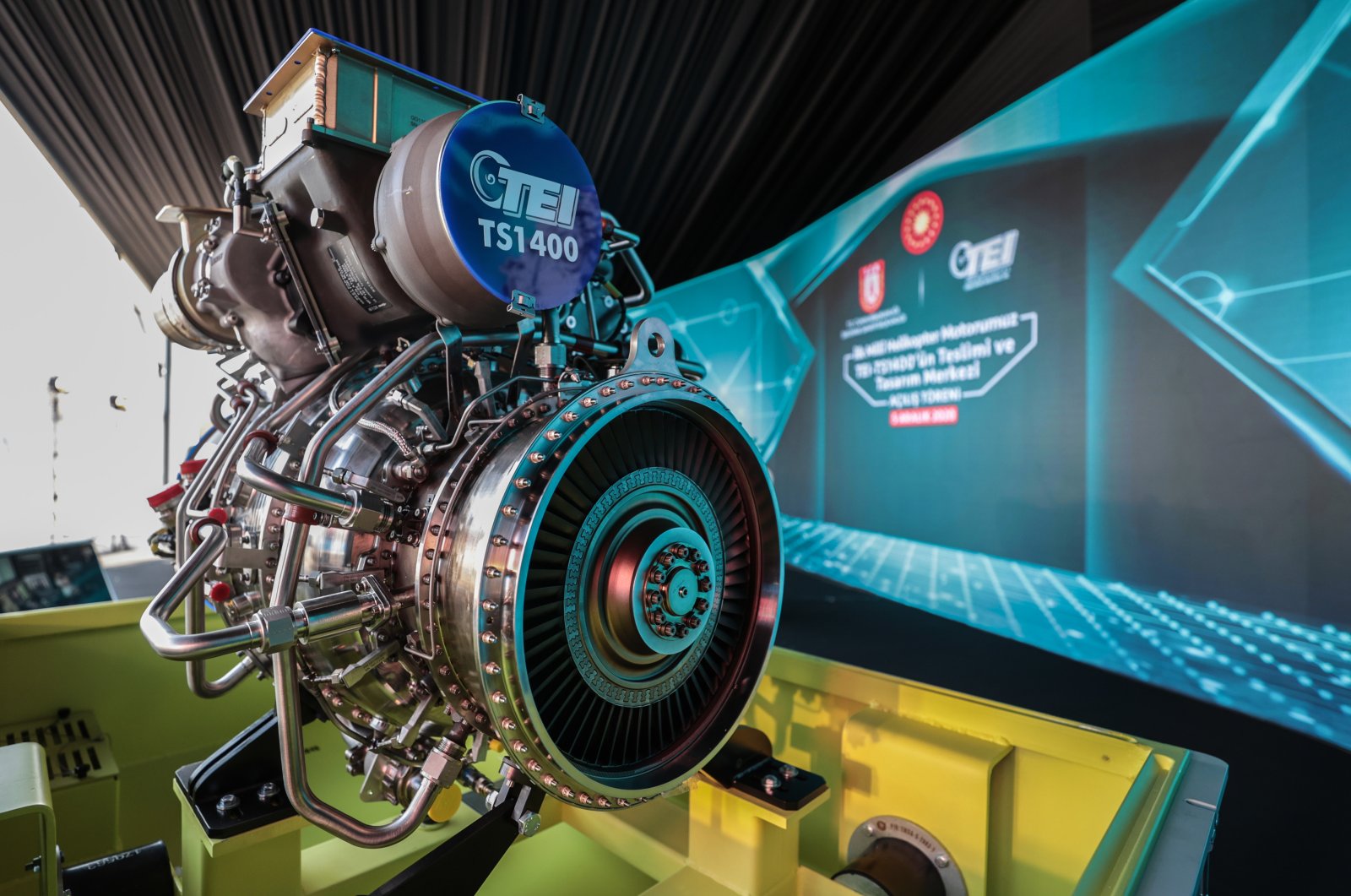

Designed and developed by the engineers at the Turkish Aerospace Industries’ (TAI) engine manufacturing subsidiary, TUSAŞ Engine Industries (TEI), the turboshaft TEI-TS1400 engine was designed for the country’s first indigenous T625 multirole helicopter named Gökbey.

The TEI will become a role model in Turkey with its planned investments in an engine development project, Erdoğan said.

A twin-engine, 6-ton-class helicopter designed for high mission flexibility even in the toughest of geographical environments and adverse weather conditions has been developed in response to growing market demand for higher mission flexibility in this class.

The T625 is being developed as part of the Original Helicopter Program, coordinated by the Presidency of Defense Industries (SSB).

The T625 prototype earlier used a pair of LHTECs, CTS800 4-AT turboshaft engines that have 1,373 shaft horsepower each, created jointly by Rolls-Royce and Honeywell.

Several tests of the TEI engine, which produces 1,660 horsepower, were done during the ceremony. The project was launched in 2017.

“With every step we take, we see once again that in the geography where we live, we can’t look to our future confidently without having a strong defense industry,” Erdoğan said.

“We plan to establish a stronger coordination system through our Presidency of Defense Industries and our executive committee,” the president added.

“In the economic policies we carry out, we’re focused on medium and long-term goals in the industry, as in every field.”

The TS1400 is also expected to be used on HÜRKUŞ training aircraft and T129 Tactical Reconnaissance and Attack Helicopter (ATAK), as well as its derivatives developed by TAI.

TEI’s Turboshaft Engine Development Project (TEDP) looks to decrease dependence on foreign sources while enabling domestic production of engine systems, which constitute one of the most important components of these projects and increasing the percentage of indigenous production in these projects.

TEI: Critical player

With its technical know-how worth nearly 35 years, strong infrastructure and qualified workforce, TEI carries out different motor and engine projects for unmanned aerial vehicles (UAVs), helicopters and missiles.

It now manufactures over 1,500 different parts for 50 different aviation engines used around the world. The company is the world’s largest supplier for LEAP motors that power the Airbus A320neo, Boeing 737 MAX and Comac C919.

TEI has developed 10 engine projects – four diesel, two gasoline and four jet fuel engines – over the last six years, keeping itself competitive worldwide.

“Turkey has now overcome the problem of motor technology,” said TEI General Manager Mahmut Faruk Akşit.

“Five of these engines have been mass-produced. They were manufactured and delivered. We have engines that have successfully flown in the sky for over 30,000 hours. Mass production negotiations of two of the engines continue. One is Gökbey’s engine. At the same time, mass production negotiations for the TJ300 engine are currently underway,” Akşit added.

“I hope that with this engine, Turkey joins Germany, the U.K. and France league, namely the Champions League in aviation,” he added.

The company produces T-70 helicopter engines as part of its Turkish Utility Helicopter Program (TUHP), using the nameplate T700-TEI-701D.

It manufactures the motors under a license from General Electric, with more than 50% of the parts contributed locally. Final assembly and testing are carried out at its facilities in the central province of Eskişehir.

The multi-role T-70 utility helicopters were custom designed, based on the S-70i Black Hawk helicopter of Sikorsky Aircraft, a Lockheed Martin Company.

It also developed TEI-PD170 engines, designed for new-generation UAVs like Anka, Akıncı and Aksungur, the country’s first two-stroke aviation motor, TEI-PG50 and the first medium range anti-ship cruise missile engine TEI-TJ300.

Engine to cut import bill by $60M

Once Turkey starts to mass-produce its own turboshaft helicopter engines, it will avert annual hi-tech imports worth $60 million, Industry and Technology Minister Mustafa Varank said.

“Today, we’re witnessing a historic day for our defense industry,” Varank said in his speech at the ceremony.

Underlining that the country is accomplishing its goals of acquiring technology and advanced design skills thanks to its National Technology Move, Varank said the engine was designed, developed and produced entirely by TEI engineers and technicians in just three years.

Turkey is one of seven countries with gas turbine engine technology, he said. “The new design center that will make the local engines will be the starting point of our new success stories.”

Varank said while the per-kilogram value of average Turkish exports is currently at $1.50 (TL 11.70), this figure is over $50 in the defense industry.

“The export value of our first national helicopter engine, the TS1400, is $6,000 per kilogram,” he added.

Source:dailysabah.com